Chennai (Tamil Nadu) [India], September 23: Entity 1 Value Emissions Pvt Ltd, India and HIT, Taiwan. Today announces a groundbreaking PoC program: silicon carbide (SiC) wafers produced from red mud-derived silicon, with testing conducted by Taiwan Semiconductor Industry professionals via HIT, Taiwan. This milestone marks India’s emergence as a global innovator in sustainable materials for the semiconductor value chain and reinforces Make in India as a strategic driver for domestic manufacturing.

What’s New

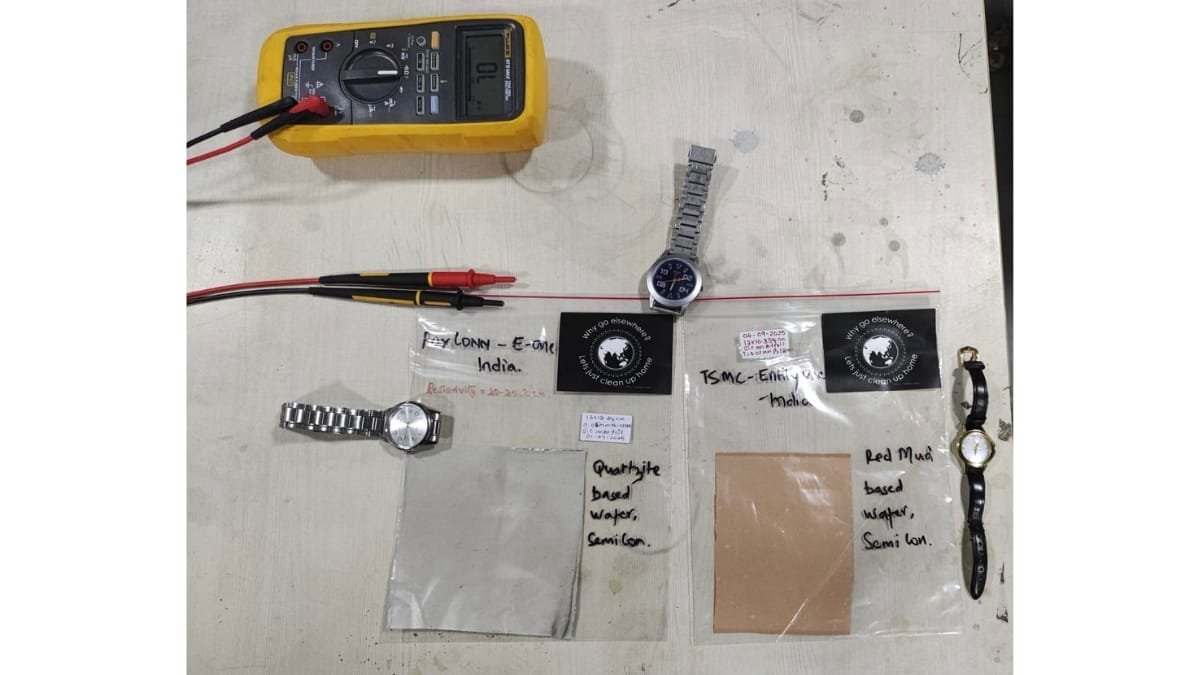

- Product: Red mud–derived silicon carbide wafers in testing-grade formats.

- Sizes tested: 7×7 mm, 10×10 mm, and 13×13 mm wafers used for PoC testing.

- Source material: Silicon derived from red mud, sourced from National Aluminium Company Limited (NALCO); silicon carbide material produced from NALCO red mud-derived silica feedstock.

- Testing partner: HIT, Taiwan, in collaboration with Taiwan Semiconductor Industry players, validating process viability and performance.

India (Make in India, domestic manufacturing, sustainability)

- Highlight India’s leadership in valorising industrial byproducts and advancing domestic supply chains for critical semiconductor materials. The Prime Minister’s office has been kept updated on the progress.

- Emphasise the collaboration with NALCO as a milestone for source localisation, enhancing energy/waste efficiency and reducing import dependence.

- Position India as a global hub for sustainable Materials & Devices, with potential licensing and technology-transfer opportunities for national champions and SMEs.

Taiwan (Global semiconductor ecosystem, quality assurance)

- Spotlight HIT’s role as a benchmark testing partner, reinforcing Taiwan’s reputation for rigorous qualification of high-performance wafers.

- Emphasise cross-border collaboration between India and Taiwan as a model for resilient, risk-managed supply chains in advanced packaging and power electronics.

- Frame the test results as enabling new materials pathways that complement Taiwan’s leading-edge fabs and ecosystem.

Shared Narrative

- A joint showcase of sustainable metallurgy and semiconductor materials innovation that accelerates Make in Asia collaboration, supports ESG goals, and diversifies regional supply chains.

- The region-specific angles should be used by regional editors to tailor coverage toward national investment, policy incentives, and industrial partnerships.

Strategic Significance

- NALCO as an approved source: National Aluminium Company Limited (NALCO) emerges as an approved feedstock source for the semiconductor value chain in India, enhancing domestic supply security.

- Make in India acceleration: This initiative strengthens domestic capabilities in silicon carbide wafers, a critical material for high-power, high-temperature devices, packaging, and power electronics.

- Global credibility: Verification from HIT, Taiwan, and collaboration with Taiwan’s semiconductor ecosystem provide international validation and potential premium for high-assurance supply chains.

- Red mud resolution: Demonstrates a scalable approach to valorise red mud, addressing environmental challenges and creating a circular economy pathway for industrial byproducts.

Customer and Industry Implications

- Supply chain resilience: Localised, certified sources for SiC wafers reduce dependence on imports and improve lead times for advanced packaging.

- ESG and sustainability: Aligns with national goals to reduce waste and emissions while expanding sustainable manufacturing footprints.

- Innovation enablement: Opens avenues for collaboration in process development, device design, and high-performance silicon carbide applications.

Milestones and Next Steps

- Completion of additional PoC tests across the specified wafer sizes with extended performance metrics.

- Qualification programs with selective fabs to validate compatibility with existing fabrication lines.

- Scaling plans with NALCO for a stable supply of red mud–derived silica and feedstock.

- Stakeholder engagement for potential licensing and reactor set-up at red mud sites.

Date: 24.09.2025

Location: Chennai, India

If you have any objection to this press release content, kindly contact pr.error.rectification@gmail.com to notify us. We will respond and rectify the situation in the next 24 hours.